Filigrana

A technique dating back to the sixteenth century used to manufacture glass objects composed of clear glass rods with a core of lattimo or colored glass filament. The rods are laid side by side, placed in the kiln, and fused together. They are then gathered at the end of the blow pipe on a cylinder of cristallo glass, which is then blown and shaped. This technique utilizes three different patterns: a mezza-filigrana, a reticello and a retortoli. In the a mezza-filigrana and a reticello patterns, rods with a single filament are used. A retortoli or zanfirico pattern is composed of at least two filaments woven into a spiral. A reticello is a pattern of diamond-shaped filaments obtained by merging, while twisting in the opposite directions, two half spheres of mezza filigrana. A more ancient variation of filigrana is the a retortoli, also known as zanfirico. This variation is named after the Venetian antiquarian Antonio Sanquirico who, during the first half of the nineteenth century, commissioned a large quantity of glass made using this particular technique. During the ’50s and ’60s maestro Archimede Seguso further developed the filigrana technique by inventing new interpretations called merletti using segments of specially prepared a retortoli rods.

Incalmo

The incalmo technique consists of joining different pieces of glass while hot, then shaping them into the desired form. If repeated, this process can create objects composed of several colored sections.

Incamiciato

Glass composed of one or more cased layers. Generally, colored transparent glass, or sometimes pasta vitrea, is laid over a base of opaque glass. This technique, which allows for sophisticated color effects, has been widely used since the ’20s and continues to be widely used today.

Massiccio

A process by which objects and sculptures of thick glass are made. Widely used in Murano since the beginning of the 1930s, it consists of shaping the glass while still malleable with the help of tools and/or molds but without blowing.

Mosaico o A murrine

First introduced in Roman times and reintroduced at the end of the nineteenth century by the Muranese glass industry, this process is based on joining sections of glass rods called murrine. The glass sections are obtained by cutting multicolored rods of glass. These rods were often produced in advance to specification, sometimes by different glass workshops, to create a floral or geometric design. The murrine are laid down in the desired pattern, fused together into a single glass mass and then blown and shaped by the glassblower. In some cases, as with Carlo Scarpa in the 1940s, molds are used and the glass is shaped without blowing. Carlo Scarpa also used two distinctive finishing processes: battuto and velato. These were obtained by carving the entire surface at the wheel in the moleria.

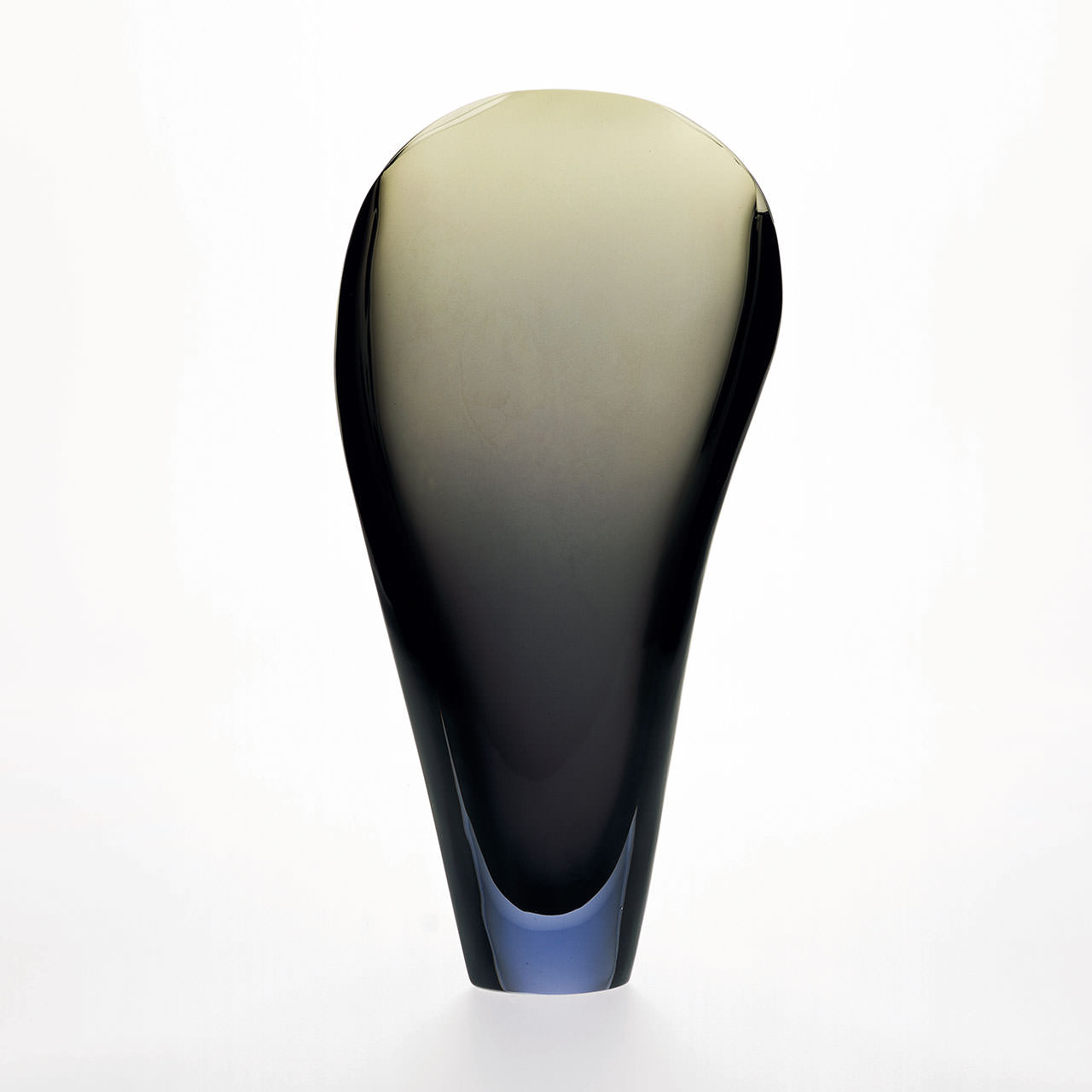

Sommerso

Glass of significant weight and thickness composed of clear and colored cristallo, which is obtained by repeatedly dipping the object during the work process into different crucibles of melted glass. There are many variations to this technique. In fact, some layers of clear glass may be substituted with other types of glass, such as glass with bubbles, called sommerso a bollicine, with gold or silver leaf. These inclusions create beautiful multicolored or multilayered effects.

Tessere

Glass composed of patches of various sizes and shapes. The tessere are obtained either by flattening segments of glass rods or by subdividing sheets of colored glass into the desired shapes. After placing them in the desired pattern on a heat-resistant flat surface, they are then fused together, blown, and shaped.

Tessuto

A multicolored glass obtained by the juxtaposition of thin vertical rods fused together. After fusing the rods, which are generally laid down in alternating colors, the maestro gathers them into a cylinder, which is then blown and shaped. In some cases the object may be finished with a fine grinding, velato, at the wheel.